Engraving Machines Direct

Your one-stop-shop for ALL of your engraving machine needs!

Scroll down and follow our quick 3-step process to determine which type of laser engraver machine is right for you.

In the market for an engraving machine?

You are just minutes away from finding the right match!

Our unique system provides all the details you need to help you make an informed decision on your own.

Take Survey & Save Time

Let our 10 years of experience work for you. After filling out the survey, our experts will get to work assisting you in choosing the right machine.

Receive Detailed Price Quote

We’ll provide you with all the in-depth details and pricing information needed to get started immediately.

Unlimited Training & Support

Leave the heavy manual reading to us. We’ll teach you how to use your new machine and provide on-demand support.

Ready to get started?

Enter your email below to start the survey.

Our experts will respond quickly with an information and pricing breakdown to keep your purchasing journey on track.

Rather speak with someone?

We understand. Our team is happy to speak with you and help you find the perfect machine!

1-786-363-9973

Follow the steps below to help you gather the information needed for the survey!

STEP 1

APPLICATION TYPES

First, let’s get some information about your application.

Answering the series of questions below will help you better understand the machine specifications you’ll need to achieve your desired outcome.

From there, we can help you determine the best fit machine for your needs.

Application

What types of items do you intend to engrave?

What materials are they made of?

Make a prioritized list of the materials and quantities you’ll be producing.

Shape & Size

What are the dimensions of the smallest and largest items you would like to engrave?

What about thicknesses and diameter?

Is the area you wish to engrave flat or is it a part of a curve or cylinder?

Throughput

How many pieces do you foresee having to engrave in a given day, week or month?

You don’t have to know the exact amounts, but a rough estimate will help ensure you choose an engraving machine with adequate speed and a duty cycle to match your projected output.

Materials You Can Engrave

Acrylic

Metal

Glass

Stone

Rubber

Paper

Wood

Textile

Plastic

Ceramic

Leather

Food

STEP 2

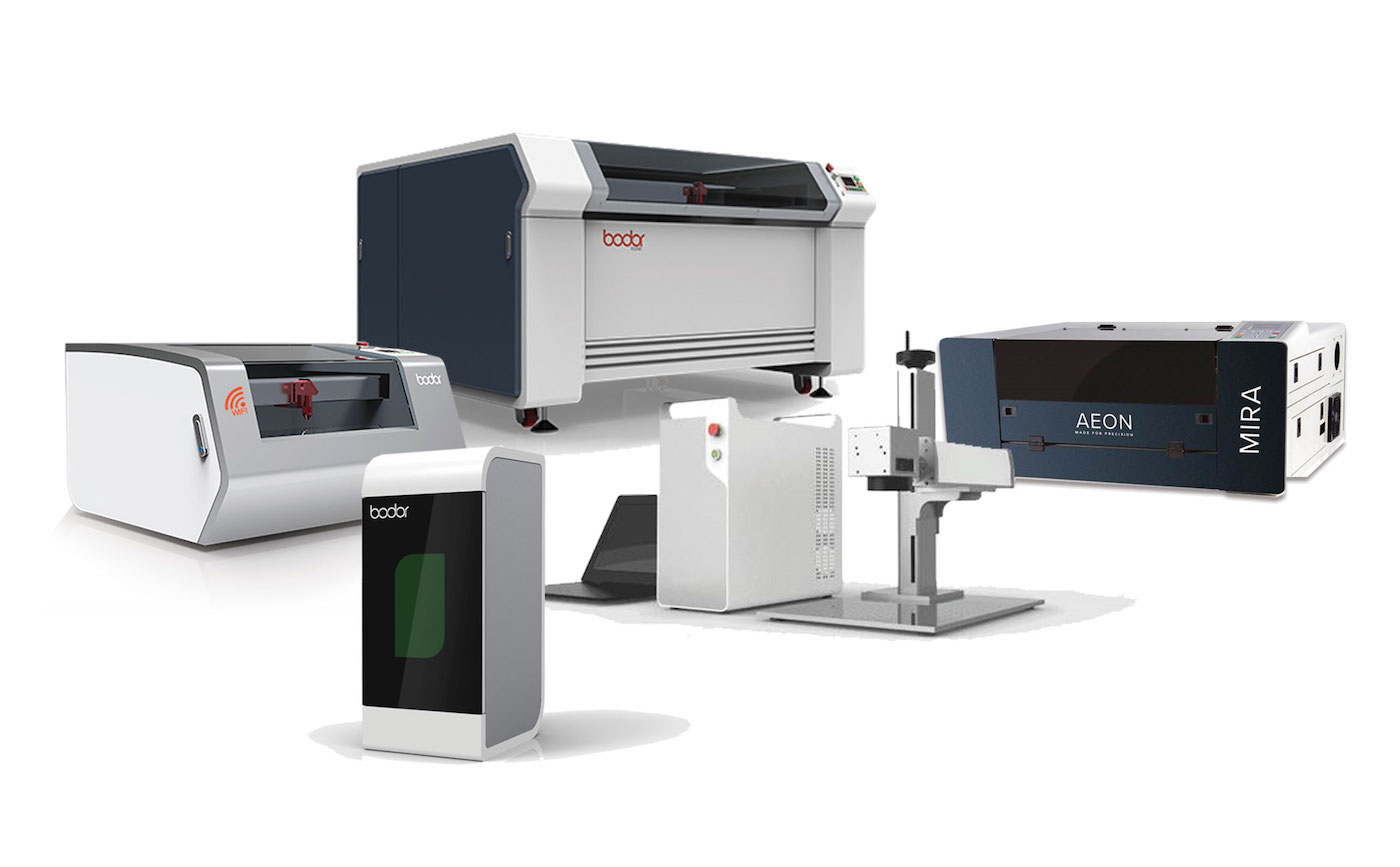

MACHINE TYPES

Next, let’s acquaint you with the best options for engraving machines.

Before making a purchase, it’s best to compare which engraving method and model best fits your needs.

Shopping for an engraving machine is a bit different from most products. Be sure to read through the specifications for each.

Rotary Engravers & CNC Routers

Rotary engravers are popular, known for their use of a spinning cutter to etch 2D and 3D labels or decorations into materials such as acryic, aluminum, stainless steel, and wood.

CNC routers are larger versions of the same machine – designed to handler thicker substrate materials such as stone, granite, and marble.

Read More

Advantages:

- Works on virtually every solid material type – including metals and various types of stone.

- Easy setup – no additional requirement components to install.

- Safe and reliable – Set up a machine in any standard environment and leave unattended with confidence!

Factors to Consider:

- Additional operation steps needed – everything needs to be clamped in place to keep the item from moving during the engraving process.

- Cost of replacement cutters can be frequent and expensive.

- Lengthy finishing processes add more time to large projects.

Dot Peen and Impact Printing

Impact printers are mainly used for personalization and photo engraving, while dot peens are solely used for permanently marking metal. Both utilize a diamond stylus to strike downwards onto the material, creating a deep indentation. Both can be programmed to engrave text and images.

Read More

Advantages:

- Marks are fast and error-free thanks to an efficient and accurate diamond stylus.

- Accurate markings will apply to rough or uneven surfaces, ensuring uniform quality on any material.

- Scaleable Machinery. Can be used as a standalone or easily integrates with a larger manufacturing system or assembly line.

Factors to Consider:

- Extremely noisy due to the impact process.

- Engraving marks not as defined as those produced from larger machines such rotary engravers and CNC routers.

- Limited engraving area. Available marking space is only as large as a standard engraving plate – such as alphanumeric codes on machine parts.

Laser Engraving Machines

Laser engraving machines utilize a concentrated beam of light to engrave or cut through a wide range of materials, including more delicate options such as cardboard, fabric, or plastic.

Read More

Advantages:

- Extremely versatile. From solid to more malleable materials, laser engraving works!

- Fast processing time. No other system can match it’s speed.

- Cost of ownership is significantly less than other options due to the absence of replacing spindles or cutters.

- Maintenance and repair are both significantly reduced due to the lack of resistance the machine encounters.

- There’s no need for clamping items into position.

Factors to Consider:

- Complicated setup and project optimization. You’ll need to know which wavelengths are favored by the materials you are intending to mark on, engrave or cut.

- The engraving process generates excess heat and fumes.

- Low tolerance for part surface irregularity, including inconsistent marks on wet or dirty surfaces.

- Laser markings are shallow by default. Deeper marks are possible, but take considerably more time.

STEP 3

SURVEY

Lastly, fill out the Equipment Fitment Guide survey.

Based on your responses, the E.F.G. will create a detailed information and pricing package that meets your unique needs. Results will be delivered by email.

One of our experts will contact you shortly after and help you choose the right machine.

In just a few hours you’ll have answers to all your questions, saved a ton of time and will feel 100% confident about making an informed decision.

Additional Aspects to Consider

Our EFG will also help you consider many other aspects that are often overlooked when purchasing your machine.

Ease of Use

Safety Precautions

PC & Electrical Requirements

Machine Workspace

Leadtime

Financing & Tax Incentives

Start Up Training

After Sale Support

Warranty & Maintenance